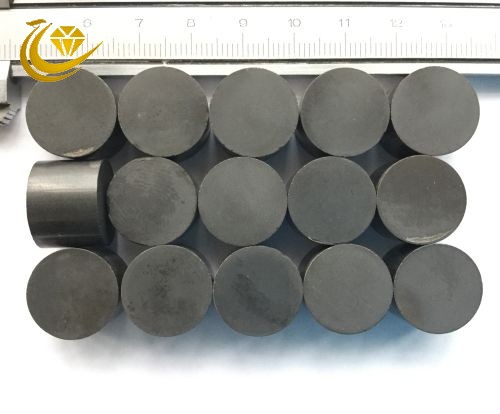

PCD拉丝模芯

PCD金刚石拉丝模坯是金刚石微粉在结合剂作用下,采用高温高压工艺烧结而成。在烧结过程中,金刚石微晶颗粒间形成高强度的金刚石键,把金刚石微粉颗粒强烈地结合在一起,形成聚晶金刚石(PCD)。PCD金刚石拉丝模坯,既具有很高的耐磨性、硬度及导热性,又具有良好的机械强度和韧性,适用于拉制铜、铝、镍、钨等有色金属、不锈钢及各种合金线材棒材管材等。

我们为您提供帮助:简单的方法来获得你需要的答案。

产品分类

- 单晶超硬材料

- 大单晶金刚石 大颗粒单晶金刚石BCD系列金刚石单晶片SCDP系列

- 单晶金刚石 人造金刚石粗料CSD系列人造金刚石细料FSD系列树脂结合剂金刚石AC系列

- 金刚石破碎整形料 金刚石破碎料CCSD系列金刚石整型料RCSD系列聚晶金刚石破碎料APC4系列

- 金刚石微粉 通用型金刚石微粉CSDM系列专用型金刚石微粉CSDM系列原生金刚石微粉ASM系列多晶金刚石微粉CSDM-PD系列

- 立方氮化硼 立方氮化硼(CBN)单晶立方氮化硼(CBN)微粉

- 镀覆产品 镀覆金刚石和立方氮化硼(CBN)

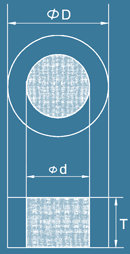

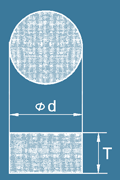

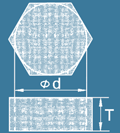

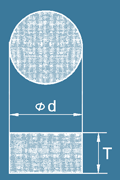

规格表

|

ADDMA |

产品代号 |

尺 寸(mm) |

粒 度(μm) |

示意图 |

||||||||

|

模坯 |

金刚石 直径Φd |

金刚石 厚度T |

最大 推荐孔径 |

|

|

|

|

.jpg) |

|

|||

|

1 |

3 |

5 |

10 |

15 |

25 |

|||||||

|

TCD系列 |

|

|||||||||||

|

T12 |

TCD4015 |

8.12 |

4.0 |

1.5 |

1.0 |

○ |

● |

● |

● |

● |

● |

|

|

T15 |

TCD4023 |

8.12 |

4.0 |

2.3 |

1.8 |

○ |

● |

● |

● |

● |

● |

|

|

T18 |

TCD4029 |

8.12 |

4.0 |

2.9 |

2.3 |

○ |

● |

● |

● |

● |

● |

|

|

T21 |

TCD7040 |

13.65 |

7.0 |

4.0 |

3.5 |

﹣ |

● |

● |

● |

● |

● |

|

|

T24 |

TCD7053 |

13.65 |

7.0 |

5.3 |

4.6 |

﹣ |

● |

● |

● |

● |

● |

|

|

T27 |

TCD13086 |

24.13 |

13.0 |

8.6 |

5.8 |

﹣ |

﹣ |

● |

● |

● |

● |

|

|

T30 |

TCD130116 |

24.13 |

13.0 |

11.6 |

7.8 |

﹣ |

﹣ |

○ |

● |

● |

● |

|

|

T31 |

TCD150120 |

24.13 |

15.0 |

12.0 |

9.0 |

﹣ |

﹣ |

﹣ |

○ |

● |

● |

|

|

T33 |

TCD150150 |

26.80 |

15.2 |

15.0 |

10 |

﹣ |

﹣ |

﹣ |

﹣ |

● |

● |

|

|

T33 |

TCD180150 |

29.00 |

18.50 |

15.0 |

11 |

﹣ |

﹣ |

﹣ |

﹣ |

● |

● |

|

|

TCD180180 |

29.00 |

18.50 |

18.0 |

12 |

﹣ |

﹣ |

﹣ |

﹣ |

● |

● |

||

|

TCD250180 |

36.00 |

25.00 |

18.0 |

14 |

﹣ |

﹣ |

﹣ |

﹣ |

○ |

○ |

||

|

TCD300200 |

41.00 |

30.00 |

20.0 |

16 |

﹣ |

﹣ |

﹣ |

﹣ |

○ |

○ |

||

|

CDR系列(圆形) |

|

|||||||||||

|

D6 |

CDR2510 |

2.5 |

1.0 |

0.4 |

○ |

● |

● |

● |

● |

● |

||

|

D12 |

CDR3215 |

3.2 |

1.5 |

1.0 |

○ |

● |

● |

● |

● |

● |

||

|

D15 |

CDR5225 |

5.2 |

2.5 |

1.5 |

○ |

● |

● |

● |

● |

● |

||

|

D18 |

CDR5235 |

5.2 |

3.5 |

2.0 |

○ |

● |

● |

● |

● |

● |

||

|

D21 |

CDR8040 |

8.0 |

4.0 |

3.0 |

﹣ |

● |

● |

● |

● |

● |

||

|

D24 |

CDR9853 |

9.8 |

5.3 |

4.0 |

﹣ |

● |

● |

● |

● |

● |

||

|

D27 |

CDR13085 |

13.0 |

8.5 |

5.0 |

﹣ |

﹣ |

○ |

● |

● |

● |

||

|

D30 |

CDR160120 |

16.0 |

12.0 |

7.0 |

﹣ |

﹣ |

○ |

● |

● |

● |

||

|

D33 |

CDR180120 |

18.0 |

12.0 |

8.0 |

﹣ |

﹣ |

○ |

● |

● |

● |

||

|

D33 |

CDR180150 |

18.0 |

15.0 |

8.5 |

﹣ |

﹣ |

○ |

● |

● |

● |

||

|

CDR220100 |

22.0 |

10.0 |

9.0 |

﹣ |

﹣ |

○ |

● |

● |

● |

|||

|

CDR220150 |

22.0 |

15.0 |

9.5 |

﹣ |

﹣ |

○ |

● |

● |

● |

|||

|

CDH系列(方形) |

|

|||||||||||

|

D6 |

CDH2510 |

2.5 |

1.0 |

0.4 |

○ |

● |

● |

● |

● |

● |

||

|

D12 |

CDH3215 |

3.2 |

1.5 |

1.0 |

○ |

● |

● |

● |

● |

● |

||

|

D15 |

CDH5225 |

5.2 |

2.5 |

1.5 |

○ |

● |

● |

● |

● |

● |

||

|

D18 |

CDH5235 |

5.2 |

3.5 |

2.0 |

○ |

● |

● |

● |

● |

● |

||

|

SDR系列(圆形) |

|

|||||||||||

|

SDR220140 |

22.0 |

14.0 |

11.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR240160 |

24.0 |

16.0 |

12.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR260160 |

26.0 |

16.0 |

13.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR280160 |

28.0 |

16.0 |

14.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR300180 |

30.0 |

18.0 |

15.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR320180 |

32.0 |

18.0 |

16.0 |

- |

- |

- |

- |

● |

● |

|||

说明:

1) ● 库存产品 ○ 订单产品

2)最大推荐孔径适用于有色金属软线,硬线直径不能超过该推荐孔径的65%。

对照表

询盘

关联产品

© 河南百利来超硬材料有限公司 版权所有 法律声明 Powered by MetInfo

顶部

简体中文

简体中文 English

English Pусский

Pусский

.jpg)

产品介绍

我公司PCD拉丝模坯料分为TCD、CD和SD三大系列,根据拉丝应用的需要,每种系列均有1微米、3微米、5微米、10微米、15微米及2O微米等粒度的拉丝模坯供用户选用。

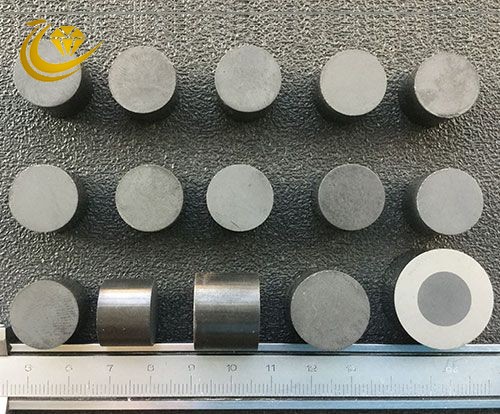

TCD系列

特征:是金刚石微粉在钴基结合剂作用下采用高温高压工艺将金刚石微粉与硬质合金支撑环紧密地烧结为一体,由支撑环来提高模坯的抗裂强度,因此这类产品能够承受更高强度及速度的拉拔,拉丝光洁度高,TCD系列模坯须在650℃以下镶套,可用电火花、激光和超声波等方法打孔成型。

用途:适用于高速拉制铜、铝、镍、钨等有色金属、不锈钢及各类合金线材棒材等硬质材料和直径较粗的材料。

CD系列

特征:金刚石微粉在钴基结合剂作用下采用高温高压工艺烧结而成,无硬质合金外环支撑,拉丝光洁度高,CD系列模坯须在650℃以下镶套,可用电火花、激光和超声波等方法打孔成型,CD系列分为CDR(圆形)和CDH(六方形)两种。

用途:适用于拉制铜、铝、镍、钨等有色金属及各类合金线材棒材等硬质材料和直径较细的材料。

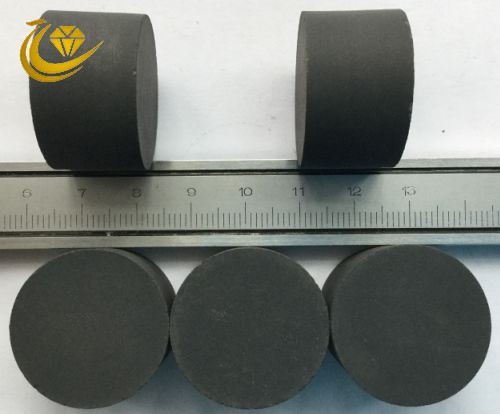

SD系列

特征:金刚石微粉在硅基结合剂作用下采用高温高压工艺烧结而成,SD系列模坯可在1000℃高温下镶套,非导电性,不可用电火花打孔成型。

用途:适用于拉制铜、铝绞线模,和消耗量较大的贱金属,如钢丝、铁丝等。